The Project: Building a stern rail mount for our dinghy motor

The why

While we are using the boat in Lake Ontario, our 15hp outboard sits on the dinghy, ready for action. When we want to go sailing, the dinghy and its outboard motor get hoisted out of the water (as one unit) and strapped to the stern of the boat. Out on the big waves of the ocean, however, both the dinghy and the outboard motor need to be more secured. The dinghy will go on the bow of the boat, while the motor will be mounted tightly to one of our stern rails. The only problem is the weight of our motor at 120 lbs. A store-bought motor mount is only rated to 100lbs. Yikes! We only had one way to go - build our own motor mount.

While we are using the boat in Lake Ontario, our 15hp outboard sits on the dinghy, ready for action. When we want to go sailing, the dinghy and its outboard motor get hoisted out of the water (as one unit) and strapped to the stern of the boat. Out on the big waves of the ocean, however, both the dinghy and the outboard motor need to be more secured. The dinghy will go on the bow of the boat, while the motor will be mounted tightly to one of our stern rails. The only problem is the weight of our motor at 120 lbs. A store-bought motor mount is only rated to 100lbs. Yikes! We only had one way to go - build our own motor mount.

The plan

Design a mount using steel and starboard (i.e. plastic wood)

Design a mount using steel and starboard (i.e. plastic wood)

The cost

Hardware $60

Aluminum diamond plate $25

Starboard $225

Total $310 CAD

Hardware $60

Aluminum diamond plate $25

Starboard $225

Total $310 CAD

Getting it done

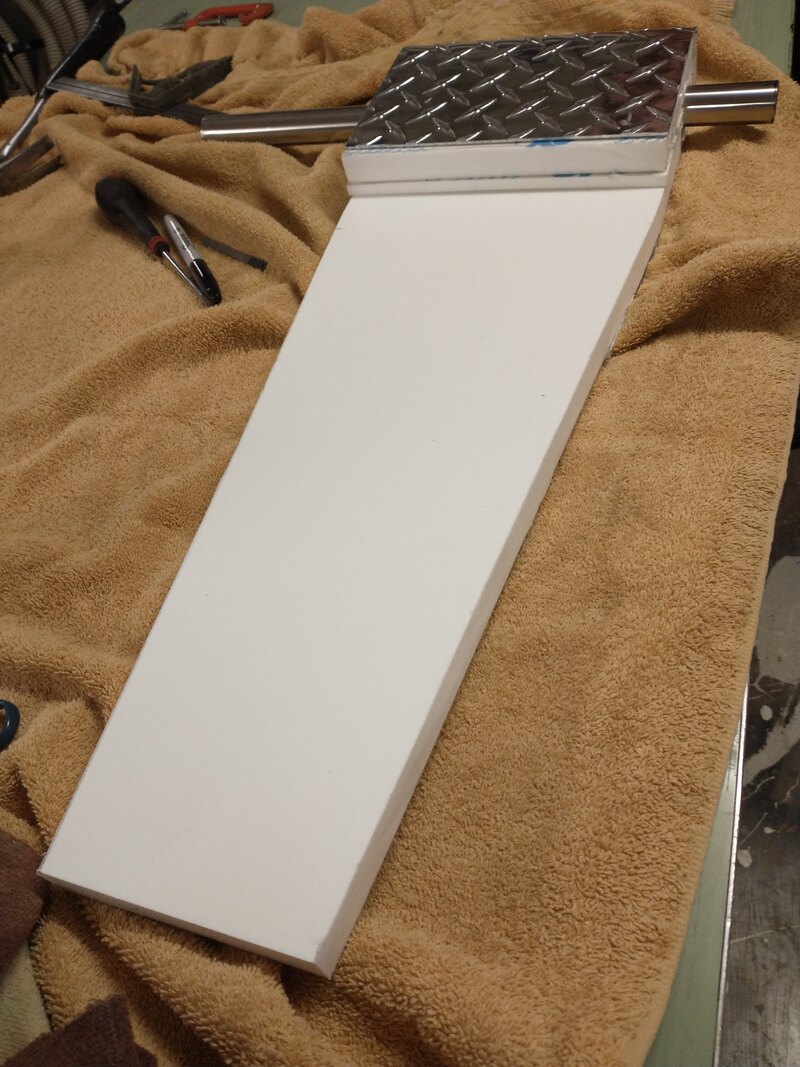

This project was one of Mike's rare "design on the go" projects. That is, he had a loose idea of how it would work but not until he started to get into it did the components of the design really come together. The idea was to build the structure out of starboard (for strength) then apply an aluminum steel plate over top to take on the wear and tear of moving the outboard on and off the mount. The more difficult part was figuring out how to get it all attached together. For this, Mike designed a supporting structure out of starboard that served as joints and connectors.

The first step was cutting the starboard. Starboard is a marine-grade polymer that acts like wood but doesn't rot and it maintains its colour and consistency forever. Truly an awesome material to use but it doesn't come cheap. One 2 x 3 piece is $200 CAD yikes! Needless to say, Mike was very nervous about making the first cuts. In addition to cutting the starboard into the correct shape, he also had to build in a grove to properly fit the steel rail on the aft of Wild Horses. Thankfully my dad's workshop had a grinding tool that did an excellent job of this.

Next was bending the aluminum diamond plate. This took some ingenuity but Mike got it done using a combination of wood blocks, clamps and sheer strength.

This project was one of Mike's rare "design on the go" projects. That is, he had a loose idea of how it would work but not until he started to get into it did the components of the design really come together. The idea was to build the structure out of starboard (for strength) then apply an aluminum steel plate over top to take on the wear and tear of moving the outboard on and off the mount. The more difficult part was figuring out how to get it all attached together. For this, Mike designed a supporting structure out of starboard that served as joints and connectors.

The first step was cutting the starboard. Starboard is a marine-grade polymer that acts like wood but doesn't rot and it maintains its colour and consistency forever. Truly an awesome material to use but it doesn't come cheap. One 2 x 3 piece is $200 CAD yikes! Needless to say, Mike was very nervous about making the first cuts. In addition to cutting the starboard into the correct shape, he also had to build in a grove to properly fit the steel rail on the aft of Wild Horses. Thankfully my dad's workshop had a grinding tool that did an excellent job of this.

Next was bending the aluminum diamond plate. This took some ingenuity but Mike got it done using a combination of wood blocks, clamps and sheer strength.

Finally, the joints and connectors were added and all was bolted into place. The end result? A beautiful motor mount that is ready for install!

And how does it look? Fantastic! Our outboard sits beautifully on the new motor mount. Oh, and for those following along closely, you can also see our new revitalized swim platform in this photo. In our eyes, the whole package looks sweet!