|

So, we had a little problem with launch day. To be fair, our “launch” actually went quite smoothly. It was a few hours post-launch that everything went sideways. I will walk you through the drama, which involves Wild Horses taking on water and ends with her getting hauled out of the water, a mere 20 hours after launch. The day started great. We got all of our pre-launch tasks done well in advance of our one o'clock launch timeslot (boat fenders and dock lines attached; dinghy was hauled up from the ground and secured on deck; standing rigging adjusted for lifting). The travel lift and crew arrived on time and no problems were encountered with the move of the boat from the cradle to the water. Perfect! Next, Wild Horses was slowly and delicately lowered into the launching well. Easy! Mike did his check for leaks (there were none) before we gave the okay for the slings to be removed. Wild Horses was successfully launched! Our plan for the rest of the day was to test the engine (can only be done in the water), attach the sails and to do a few other things to make Wild Horses “season-ready”. We would then stay overnight and return back on Thursday to set sail for Kingston (Wednesday would be spent in Trenton celebrating my dad’s 81st birthday).

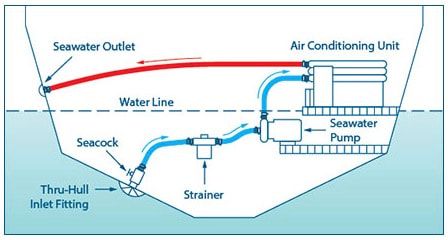

Everything had been going very smoothly and quickly so by late afternoon we had some extra time to test the boat’s air conditioning, something we normally do once docked in our slip in Kingston. Unlike land air conditioning systems, a boat uses water for cooling rather than air. The water for this system is pulled into the air conditioning system with a pump that draws the water through a hole in the bottom of the boat. The hole is regulated with a thru-hull and seacock so water only comes in on demand. We open the seacock, turn on the air conditioning and the pump starts drawing water from the lake. And voila! The inside of the boat gets cooled down within 15 minutes. But that isn’t what happened late afternoon on Tuesday. Mike opened the seacock and water started to flow… but not into the pump. It started to flow into the boat (technically it flowed into our bilges, which is the space below the floorboards). Thankfully, closing the seacock stopped the flow of water so we had time to inspect the problem. And, there it was. On the underside of the thru-hull valve was a crack. This is a critical failure – one that could easily sink the boat. The only thing that was keeping Wild Horses dry and floating was a broken seacock. Wild Horses needed to get out of the water to save her from sinking and to get that thru-hull fixed. It was now late in the day and all the marina staff had gone home so we knew haul out would have to wait until the morning. That night was very long but the seacock held and the water stayed out. First thing the next morning, the marina staff hauled Wild Horses out of the water and moved her back onto her cradle. She was finally safe once again. The fix is simple – we need the failed thru-hull removed and a new one installed in its place. This is work we would normally do ourselves if we had a few weeks to research and play around with how it is done. Since we want to be back in the water quickly, we have a boat mechanic doing the fix. Wild Horses should be back to her old self by the end of the week so we can plan her re-launch. Boating has its ups and downs. For us, there are far more “ups” so the occasionally “down” like this won’t impact us much. We know the cause of cracked thru-hull (one step in our winterizing was missed – big oops!) so we take this as a live and learn experience. Luckily, at the end of the day, the only damage was to our pocketbook and our egos. But both will survive this and, soon enough, we will be looking forward to our re-launch! Comments are closed.

|

AuthorVictoria is a hiker, dog-lover, blog writer and planner extraordinaire. Oh, yeah and she is kind of fond of living on a boat. Categories

All

Archives

June 2024

|

RSS Feed

RSS Feed